Cost-efficient Techniques for Packaging Machine Repair and Upgrades

Cost-efficient Techniques for Packaging Machine Repair and Upgrades

Blog Article

Making Sure Smooth Procedures and Cost-Efficiency: The Important Benefits of Spending in a High-Performance Packaging Machine

Investing in a high-performance packaging maker can considerably affect the operational performance and cost-effectiveness of a manufacturing center. As industries browse a significantly affordable landscape, the critical of leveraging advanced modern technologies like high-performance packaging equipments ends up being not simply a requirement but a choice.

Enhanced Performance and Output

Investing in a high-performance product packaging equipment can dramatically increase efficiency and output in a manufacturing center. These machines are crafted to operate efficiently, guaranteeing seamless product packaging processes that save time and sources. By automating tasks such as filling up, sealing, labeling, and palletizing, high-performance product packaging machines streamline operations, minimizing the requirement for manual work and minimizing the risk of errors.

Moreover, these devices are designed to function at optimum rates while maintaining precision and consistency in packaging, causing greater outcome degrees. With innovative modern technology and features like automated changes, top quality control systems, and real-time monitoring, high-performance product packaging makers can take care of a wide variety of packaging requirements effortlessly. This flexibility allows suppliers to meet differing manufacturing demands without compromising on high quality or efficiency.

Decreased Downtime and Delays

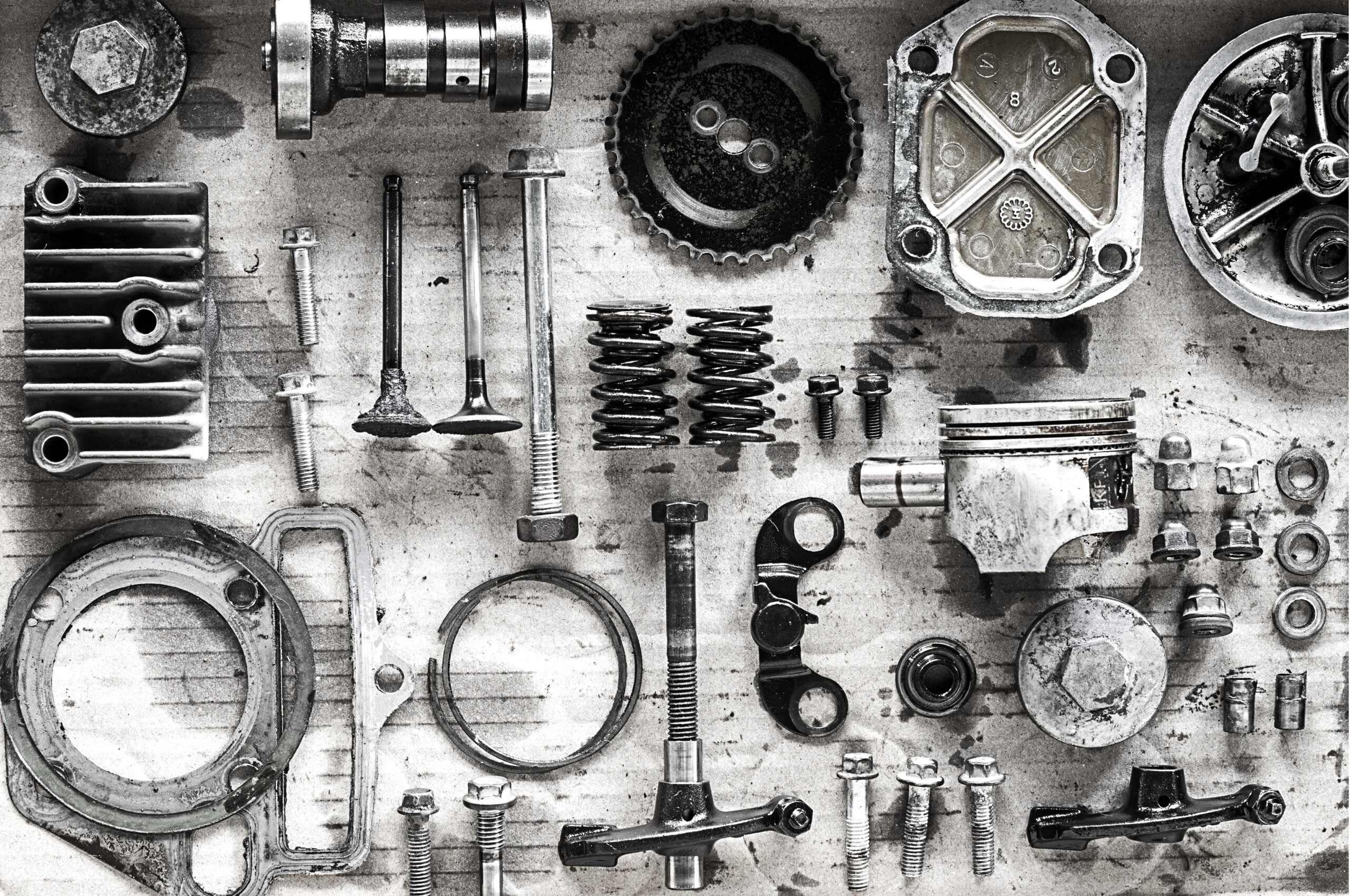

To maximize functional performance, high-performance packaging machines are engineered to decrease downtime and hold-ups in production processes. By including sophisticated modern technology and durable design components, these makers can detect problems proactively, execute self-diagnosis, and also implement fixing actions without human treatment. In addition, anticipating maintenance features make it possible for prompt maintenance of parts before they fall short, preventing unanticipated breakdowns that can stop production.

In addition, high-performance product packaging machines are furnished with effective changeover systems that promote quick shifts between various item types or packaging styles. This capacity reduces the moment needed for arrangements and changes, thereby minimizing downtime connected with reconfiguring the machine for differing manufacturing needs. Automation functions such as automatic reel splicing and continuous operation monitoring add to uninterrupted manufacturing runs and smooth process management.

Improved Quality Assurance Actions

Enhancing top quality control steps in product packaging processes is essential for making certain item consistency and conference consumer expectations. Executing a high-performance packaging machine can significantly enhance quality assurance by minimizing errors and defects in the product packaging process. These makers are furnished with sophisticated modern technologies such as sensing units, cameras, and computerized inspection systems that allow real-time surveillance and detection of any inconsistencies from top quality requirements.

By purchasing a high-performance product packaging device, firms can establish strict quality assurance procedures that assist in recognizing issues early in the manufacturing cycle. This aggressive technique enables prompt restorative actions to be taken, minimizing the chance of defective products getting to the marketplace. Furthermore, the precision and precision of high-performance packaging makers add to the total high quality guarantee procedure, making certain that each product is packaged correctly and fulfills the needed requirements.

Expense Cost Savings and Performance Gains

Better high quality control measures attained through the implementation of high-performance product visit here packaging makers not just improve item uniformity however additionally pave the means for significant cost savings and effectiveness gains in the packaging process. By ensuring that each item is accurately evaluated, sealed, and classified, these machines lower the probability of mistakes that can cause costly rework or product recalls. In addition, high-performance packaging machines run at greater speeds and with better accuracy, raising total production effectiveness and outcome.

The automation abilities of high-performance packaging devices improve the product packaging process, minimizing the requirement for hands-on labor and the linked labor expenses. On the whole, investing in high-performance packaging machines results in concrete expense financial savings, improved functional performance, and boosted competition in the market.

Lasting Product Packaging Solutions

The integration recommended you read of lasting practices into packaging solutions is ending up being increasingly essential in modern sectors. As customers become extra ecologically conscious, companies are under pressure to reduce their eco-friendly footprint. Sustainable product packaging options provide a method to meet this demand while additionally enjoying various advantages.

One secret benefit of sustainable product packaging is its favorable influence on the environment. By using eco-friendly materials and decreasing waste, business can help lower contamination and save natural deposits. Additionally, sustainable packaging can improve brand online reputation and draw in ecologically aware consumers.

Furthermore, investing in lasting product packaging solutions can cause set you back savings in the future. While first application expenses might be higher, decreased material usage and enhanced functional efficiency can lead to reduced expenses with time. Conforming with regulations concerning sustainability can assist business stay clear of penalties and fines.

Final Thought

In verdict, buying a high-performance product packaging machine offers various benefits such as boosted efficiency, minimized downtime, enhanced high quality control, expense savings, and sustainable packaging options. These benefits add to smooth procedures and cost-efficiency within a manufacturing atmosphere. By incorporating advanced modern technology and automation, businesses can optimize their packaging procedures, increase result, and keep top quality criteria while minimizing functional expenses.

With advanced modern technology and functions like automatic adjustments, high quality control systems, and real-time tracking, high-performance product packaging makers can take care of a wide range of product packaging demands with ease. Applying a high-performance product packaging device can considerably improve quality control by lessening mistakes and flaws in the packaging process. packaging machine repair.Improved top quality control procedures Website attained via the implementation of high-performance packaging devices not only enhance item uniformity yet also pave the method for significant cost savings and performance gains in the packaging procedure. The automation capacities of high-performance product packaging equipments enhance the product packaging process, reducing the demand for hands-on labor and the associated labor expenses.In verdict, investing in a high-performance packaging equipment offers many benefits such as improved efficiency, decreased downtime, boosted quality control, expense financial savings, and lasting packaging services

Report this page